The production of any digital wallpaper always begins with the processing of a digital image. It can be a drawing, a photograph, a graphically executed design, any scanned document or a combination thereof, which are prepared for printing using various computer programs.

Digital wallpaper for walls

Digital methods for obtaining a pattern on the wallpaper differ quite high cost of printing one roll. However, these costs are usually compensated for by the absence of the need for printing costs, which is inevitable when applying earlier printing methods.In addition to saving money, digital printing also has the following advantages:

- Short work due to high speed printing;

- the ability to execute private customer orders (manufacturers can print to the wall your favorite images and photos);

- the ability to make changes to the wallpaper design (template) at no extra cost.

Despite the fact that digital printing appeared only a few decades ago, for its relatively short history it has made great progress and today already has a large number of varieties.

Printing by dry transfer

This method of drawing the picture is carried out on large machines, the width of almost 140 cm. The technology of its implementation is a bit like drawing through a carbon paper: a special substrate with a previously applied image passes through a device in which, under the influence of pressure and heat (absolutely without moisture), the pattern is transferred on the surface of the wallpaper. Simultaneously, a protective layer of polymeric laminate is applied to the image, which will ensure the preservation of the image for a long time.

Sublimation printing (thermal transfer printing)

This method of obtaining a drawing was invented in 1957. It is widely used for painting not only wallpapers, but also textiles, various advertising and souvenir products, ceramic tiles, aluminum, etc.

In sublimation printing printers, plastic film with blue, purple, yellow and black dyes is used to transfer the pattern to paper.

Film for sublimation printing

Thermal print head, consisting of thousands of heating elements capable of accurate temperature changes, moves over this plastic tape. When it is heated, the dyes evaporate and impregnate the glossy surface of the paper, and then return to the solid form. Precise temperature changes are responsible for different color densities - the higher the temperature of the heating element, the more the dye evaporates.

Dye Sublimation Printer

Evaporated paints, absorbed in the paper, create gentle gradations along the edges of each pixel. It is important to note that the patterns obtained in this way are less faded and distorted over time.Inkjet printing

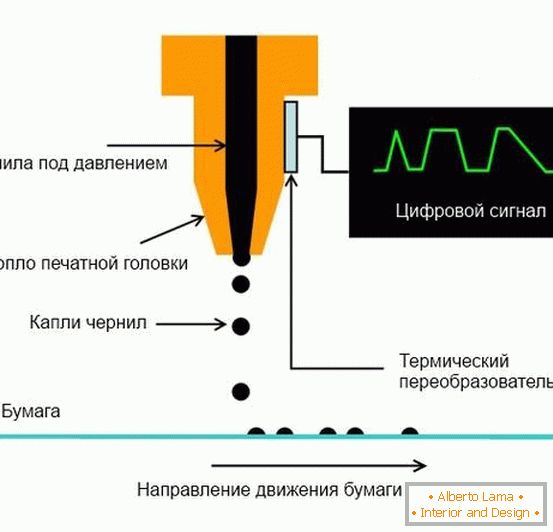

This is a special type of printing, during which extra small droplets of ink are sprayed onto the surface of the paper. One square millimeter can have from 10 to 30 such points, so they are completely invisible to the naked eye.

Different types of inkjet printers produce their ink droplets in different ways, using thermal (including Bubble Jet), piezoelectric or hybrid technologies. The most popular of all is the Bubble Jet method, developed by the famous company Canon in the late 70's.

Inkjet printer from Canon

In a printer for such printing, a special heating element creates heat (about 500 ° C), due to which small bubbles of gas form in the ink. These bubbles push ink droplets out of the multiple nozzles of the print head directly onto the print object, so that it gets its pattern.

Inkjet printing process

Designers of wallpaper often use inkjet printing to create beautiful reproductions of original two-dimensional works of art, as well as photographs and computer graphics. Such reproductions at first sight are very difficult to distinguish from the original. They're called giclée (giclee) and are obtained through the use in print of archival inks, substrates and various methods that promote the artificial "aging" of wallpaper.Giclee can reproduce the subtlest nuances of shades and light-and-light colors, thus transferring the character and texture of the brushstroke, performed by the artist.

Giclée Wallpaper

Laser printing (electrography)

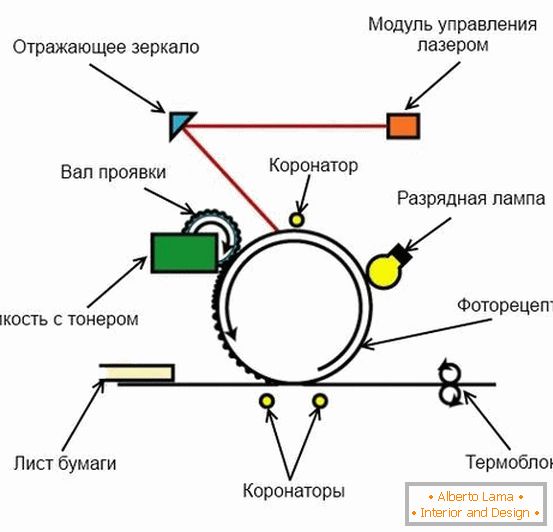

The work of laser printers is based on the principle of static electricity, which arises from the friction of objects against each other. The main component of the laser printer is a photoreceptor (usually a rotating drum made of aluminum and coated with a photosensitive material).

Scheme of laser printing process

When the drum rotates, the laser beam illuminates its surface at certain points, thereby reproducing an image that is intended for printing. After that, the drum is covered with positively charged toner, which clings only to the discharged areas of the drum (laser pattern), but not for the positively charged background. With the pattern already attached, the drum passes through a roll of paper, which before it received a very strong negative charge. The strength of this charge allows the paper to pull out the toner on itself. To save the picture, the wallpaper is released from the charge immediately after taking the toner. Finally, the roll passes through a thermoelement (a pair of heated rollers), which melts the toner powder, allowing it to merge with the paper fibers.

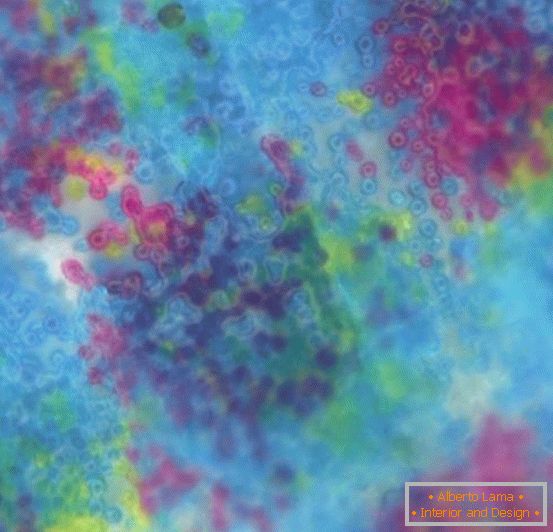

Multiply magnified image, made by laser printing

Compared to inkjet printers, laser has such advantages as: high speed and accuracy of printing, compact focusing, allowing to give high resolution, and non-compliance of prints to violations due to high humidity. Nevertheless, it is recommended to print halftone images on a wall (for example, own photos) after all on inkjet printers, which give them the best quality.

Wall-papers made to order

Large format printing

Initially, all the existing giant printers in the world, some of which cost more than one million dollars, were intended for the visualization of billboards. Today they are printed with banners, wall murals and many other large-scale images. Individual characteristics of large format printers vary depending on the type of machine and the manufacturer, however, all prints from them are subject to similar use.

Large format printing printer

Despite the fact that technological processes are constantly evolving and changing, the general classification of large format machines remains unchanged - they are airbrushing systems in which air is displaced and sprays ink under pressure, without any thermal or electrostatic impact. This method of printing allows you to use a variety of types of paints and inks, as well as various substrates, including paper rolls, fabric canvases and carpeting.

Large format wallpaper printing

Digital photo printing

With proper production, the end result of digital photo printing is a real photographic reproduction of a digital file, made without visible points and with proper care capable of preserving its beautiful appearance for many years.

Photo printing

Photo wallpapers are usually printed on paper covered with a special photo emulsion. At the print stage, the printer converts the digital information from the file into pixel data via RIP (Raster Image Processor) software. Then photo paper is fed into the machine. To affect it in some printers, lasers are used, in others - light emitting diodes (LED).Some of the laser printers process paper with a large drum, but it remains stationary and is exposed through laser beams and associated moving components (usually a mirror rotating at high speed). The dimensions of the drum limit the total size of the printing cloth to 120 "in length and 50" in width.

The rest of the laser printers and LED printing machines use a linear path that the paper passes through lasers or a long row of LEDs. This type of printing process allows you to create wallpaper much longer, but with a width still up to 50 ". Future technologies promise to increase the maximum width of wallpaper to 80 ", but do not forget that wallpaper without seams - it is beneficial only at first glance, because a sheet size of even 50" wide is very difficult to glue to the wall without damage. This work can only be done by professionals who have extensive experience with similar wallpaper sizes.

At the exit from the machine, photo paper is placed in an opaque container and delivered to the processor, where it is processed by a series of photochemical substances. After this, the finished wallpaper has to go through the final stage of production - lamination.

Laminated wall paper in the bathroom

Lamination of photo wallpapers is a necessary measure to protect the image from ultraviolet radiation, moisture, as well as from all sorts of scratches and fingerprints. Laminate is usually made of materials such as polyester, polypropylene or acetate. At the same time, it is necessary to avoid the use of PVC materials that release chlorine gases that promote the decolorization of photographic materials within a short period of time. The thickness of the laminate depends on the degree of protection required, in addition, its surface can be matte or glossy.