Ideal option for creating a unique interior in the house or workplace, without capital investment of finance and labor, will be the decoration of the room with wall panels. Such a solution can be seen almost everywhere: in shops, cafes and restaurants, offices, office buildings, railway stations, airports, houses. A wide field for design gives the format of products. They can be reticular, tiled and large (leaf). A successful combination of elements of the same series, but of different colors, creates unique solutions. The choice of material for the most part will be determined by the appointment of the room. For example, for offices, products from chipboard or MDF are good. A stone and glass will be appropriate for rooms with high humidity, or on the external facade of a public or residential building. The tree harmoniously fits into any interior style, the restriction for some breeds will be only high humidity of the room.

Like any human creation, wall panels have drawbacks:

| Friability (applies only to plastic products). | They can crumble or crack from a slight mechanical impact. |

| Fire hazard. | The materials from which the wall coatings are made are flammable and can be ignited from high temperatures or open flames. |

| Toxicity. | In case of fire, the material of the plates emits harmful substances that poison the body. With careful operation, observance of fire safety measures, you can avoid the above situations. |

Kinds

The assortment presented in building shops, is limited to three basic kinds: dial-type rack, tiled, sheet.

Rack

Long (240-370 cm) and narrow (12,5-30 cm) elements, with a thickness of 8 to 12 mm, remotely resemble racks, where they got their name. Their dimensions are excellent for plating small rooms with many angles. Installation involves the preliminary creation of a metal or wooden crate. Panels are connected with each other by the "spike-groove" method, or with the help of a tab, if the elements have only grooves. The design is fixed with special brackets, which are inserted into the crate. Or self-tapping screws that twist into the groove. Made from MDF, chipboard, fiberboard, PVC. Also there are additional accessories (stubs, skirting boards, corners, etc.).

Tiled

They are produced in the form of a square with a side of 30-98 cm. They are joined together according to the "groove-insert-groove" principle. For fixing to the wall, glue or clamps are used. The main difference is the ability to dock them with different faces, creating individual unique patterns on the wall.

Read also: Glass blocks in the interior of the apartment

Sheet

Of the three species, the largest are 1.22 m in width, 2.44 m in length and 6 mm in thickness. The face surface is ennobled with a multi-layer structure with a pattern or texture with imitation of natural elements. Installation is carried out on a special glue. Joints hide the moldings included in the delivery. Such panels can cover large areas in a short time. Materials used in the production - PVC, or impregnated with resin fiberboard.

Materials

For production use both natural natural, or made on the basis of natural components of materials, and products of the chemical industry. The first include: an array of wood, fiberboard, particle board, MDF, gypsum board, gypsum, glass. For the production of second use of PVC. Often manufacturers use just two or three types of materials, combining organic chemistry with artificial substances.

PVC

Панели из этого материала составляют большую часть, продаваемых на рынке. Выпускаются всех трёх видов исполнения. Популярность данного материала обусловлена универсальностью, т.е. возможностью применения в помещениях различного назначения и любых климатических условиях. Поливинилхлорид легко обрабатывается, принимая любую форму, прямо на него можно наносить различные рисунки, узоры, фото. Можно легко воспроизвести имитацию кирпича, кафеля, доски, камня или мраморной плиты. Основными изъянами плит PVC считаются хрупкость, горючесть, токсичность при сильном нагреве.

MDF

По составу схожи с DBP, но имеют меньшую плотность. По этой причине MDF иногда называют «мягким» DBP. Но за счёт такой «мягкости», у плит повышенные тепло- и звукоизоляционные свойства. В процессе производства им придают и другие свойства. Например, используя в качестве облицовки PVC, можно добиться хорошей влагоустойчивости плит. Специальные составы, которыми производитель зачастую пропитывает панели, делают их огнеупорными. Подобные технологические манёвры не могут не сказаться на росте стоимости, но это вполне оправданная тенденция.

Гипсониловые

They can be called the modernization of plasterboard. An interlayer of cardboard was replaced here with a vinyl layer. From such material it is possible to make walls, partitions, ceilings. Drywall is noticeably inferior to gypsum in strength, durability, marketable appearance. The latter does not require painting, since it already has a ready-made pattern or other coloring. Initially, such a product was intended for public buildings with a large flow of people, but eventually became used for private housing.

DBP

Распространённый материал в индустрии производства стеновых панелей. При изготовлении используют древесные волокна, которые соединяют между собой методом горячего прессования. Преимуществом таких плит являются низкая себестоимость, экологическая чистота, возможность ламинирования шпоном, пластиком. Иногда можно встретить DBP, обитые рейкой из натурального дерева. Выпускают всех трёх видов исполнения. Плиты крепятся непосредственно на стену, либо на предварительно смонтированную обрешётку. Между собой их соединяют замковым способом или методом «шип-паз».

Не рекомендуется отделывать плитами DBP помещения с повышенной влажностью, поскольку от сырости они сильно деформируются и отходят от стен.

Chipboard

Производят из отходов деревообработки. Поэтому они по многим параметрам уступают натуральному массиву дерева. Но все недостатки с лихвой покрывает низкая цена. Чтобы придать листам Chipboard презентабельный вид, их покрывают пластиком. Цветовая гамма пластикового покрытия может быть самой разнообразной. В процессе изготовления древесная стружка смешивается с клеевым составом и прессуется. Используемый клей токсичен и вреден для человека. Но наличие пластикового покрытия нейтрализует этот фактор. Как и DBP, плиты из стружки не выдерживают высокой влажности, сильно разбухая. Большой удельный вес (выше, чем у распространённых пород дерева), накладывает ограничения на форму выпуска Chipboard. Их производят только листами.

Read also: Decorative panels for interior decoration of walls

Of wood

In the rooms finished with natural wood a feeling of warmth and comfort is created. And these feelings do not come easily to you. People have long known the heat-insulating properties of wood. And the essential oils contained in the fibers, have a beneficial effect on the lungs, with a calming effect. The more expensive the array is, the more pronounced the above properties. The most popular raw materials for the production of wall panels made of wood are such species as oak, alder, walnut, maple, linden, cedar, bamboo. Fans of the classical Western style will really like the panels, finished with natural veneer. And for fans of oriental notes in the interior of their homes, matt panels made of bamboo are more suitable. They are weaved by hand from the stripes of bamboo, impregnated with a special glue to give the presentation and prolongation of the service life.

For those who decided to trim a wooden panel with a bathroom or a sauna, on sale there are products covered with a special water-repellent varnish or wax, which when heated does not emit harmful substances to humans.

Embossed 3D panels

The emergence of 3D panel technology can be considered a shock therapy for the design of a modern interior. Arranging the composition of such elements, you can completely change the visual perception of the reality of the internal space of the premises. As a result of the work of numerous designers, a large number of spectacular interiors for private housing and public places appeared. The principal differences between such decor elements from their two-dimensional counterparts can be characterized by the following points:

- Correctly selected composition can create the effect of reincarnation of reality, reducing or increasing the size of walls, their geometry, zoning the room without using bulky partitions;

- It became possible to create a relief and texture that is not characteristic of the material being processed;

- Properly used lighting creates a special mood in the room, decorated with relief panels, a feeling of surrealism.

The opportunity to use the third dimension to create patterns on the surface gave a powerful impetus to the creation of an infinite number of invoices, which annually supplement the assortment of building catalogs. There are invoices with already applied decorative coating, and there are requiring the application of the finishing layer (enamel, veneer, film, decorative plaster) after mounting on the walls. This gives an even greater field for creativity.

The new design find has expanded not only the boundaries of space, but also the range of materials, here are the most popular:

- Polymer composites;

- Кожа или её имитация из плёнки PVC на основе из MDF;

- Fake diamond;

- Glass;

- Natural wood, mostly bamboo;

- Decoacrylic - a substitute for glass;

- Gypsum;

- Metals, mostly colored (copper, bronze, brass), aluminum, stainless steel;

- Feather or felt. Such panels have excellent sound insulation;

- Begassa reed (squeezed green mass).

From the list you can see that the main raw material for production is environmental natural materials.

Mounted relief panels on the metal profile, while there is a gap between the wall and the back side, which can be used for laying wiring, laying insulating material. The main drawback of such elements, as well as their dignity, is their relief surface, which though looks impressive, but constantly collects dust, requiring frequent wet cleaning.

See also: We place TV in the interior + photo examples

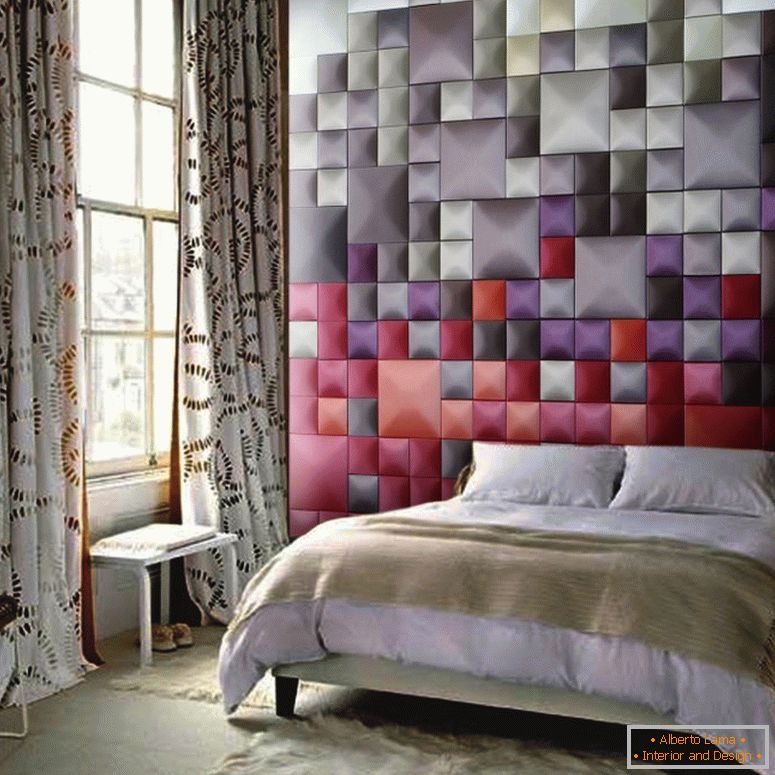

Soft panels

The current fashion trend of volumetric decor has added popularity to soft wall panels. In addition to the aesthetic component, this type of finish has a number of other advantages:

- Ease of installation;

- Beautiful soundproofing;

- Can be mounted on uneven walls. After the installation of such panels, all irregularities are smoothed by their texture;

- The ability to apply a variety of color solutions.

Due to the design features, the list of materials for the front of the panels is limited to three positions:

- Genuine Leather. Expensive and stylish stuff. Such upholstery will be appropriate in official places: conference halls, restaurants for business meetings, a study;

- Artificial leather;

- Textile. Although this is the most budgetary option, but at the same time provides the possibility of a wide choice of colors. Good fit in the interior of the bedroom.

Для наполнения используются поролон и синтепон. Первый позволяет создавать пышные и мягкие конструкции, а второй более лёгкий и не слёживается со временем. Основой может послужить лист DBP или Chipboard.

To fix this coating on the wall, use a sealant for massive decor items. This is the most popular method of installation. The second way is to fasten the panels to the lathing with self-tapping screws or nails. After the completion of installation work, it is necessary to cover their caps with plugs.

The main difficulty that will have to face after installation is the fixation on the wall of additional interior items: paintings, hangers, sconces, sockets. With small elements you can still figure out by attaching them to a soft base, but it's not easy to hang a heavy shelf or a bracket for a TV. Therefore, we must prepare for such difficulties in advance, making adjustments to the upholstery plan.

Where to use in decoration

Wall panels in the interior can perform a variety of tasks: from the decorative function, to hiding the wiring, various wall defects, insulation, noise insulation of the room. If the practical side of things is simple, then the decor is more difficult. There are several methods of distributing panels on the plane of the wall, which will help achieve the maximum aesthetic effect:

- Only part of the wall. Traditional reception, when the panels are fastened at the bottom of the wall. In this case, try to keep the proportion of 1: 3, i.е. they should not be located above the lower third of the wall. This will create the effect of high ceilings. Good for living room, corridor, hallway, nursery, kitchen, bathroom;

- On the whole wall. This option is a classic, emphasizes the status of the room. It is better to abandon its use for too small rooms with low ceilings, as the design will make the room more heavy. Do not resort to such a reception in the rooms where you spend most of the time. Here the most appropriate are the wooden panels. Suitable for library, billiard room.

- Accent on the decor. With this option, select a certain section of the wall or several intervals for the design of panels. In this case, you do not need to tie the height of furniture and decor items to a certain value, as in the very first reception. Here, you do not heavier space, if you put all the interior items correctly. It will look good in the bedroom, living room, hallway.

And do not forget - the final choice is always yours!