Recently, a large number of people prefer natural materials in the construction of housing, in particular, install wooden windows. They are installed both for glazing the house, and for terraces, outbuildings, etc. The growth of popularity of wooden windows is caused not only by natural and ecological material, but also due to its external attractiveness and high technical parameters.

Windows made of wood can be made in almost any design, which allows you to install them in any building or building - both in the industrial hall and in the country house.

They will not only glaze the room, but also decorate the veranda or gazebo in the garden, perfectly complementing them with their design and texture. Elite wooden windows, which are made of expensive wood, emphasize the man's wealth and status.

Some manufacturers of plastic double-glazed windows trim their windows under a tree, but the appearance of this window is inferior to natural wood. Installation of such windows is quite difficult, therefore it is recommended to contact specialists (now this is not a problem - most companies offer windows and their free installation). Below is a short description of the advantages and disadvantages that a tree has, variants of popular designs, in which elite wooden windows are often made, the technology of their production.

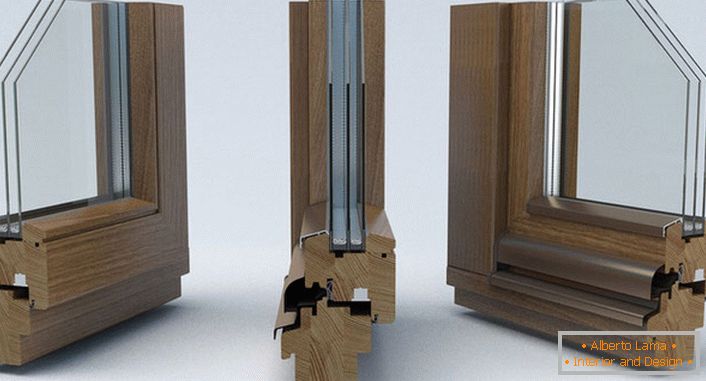

So it looks like a frame and a window with a double-glazed window made of glued beams.

Not cheap pleasure - windows made of glued oak with double-glazed windows.

In this article, read:

- 1 Pros and Cons of the Material

- 2 Manufacturing of wooden windows

- 3 Installation of glass, seal and accessories

- 4 Creative design

- 5 Modern wooden windows and their features. Video

- 6 Advantages of modern wooden windows

Pros and cons of the material

The tree is one of the most environmentally friendly materials, which is non-toxic, not dangerous for human life and health. At the moment, elite wooden windows are quite expensive, because wood is not the cheapest material. The most important advantage of making wooden window frames is the ability to regulate the humidity and good insulation performance. Windows installed in buildings (wooden) effectively do not allow the leakage of heat energy from the building to the street. At the same time, the wooden double-glazed windows carefully adjust the details, which eliminates the need to glue windows with paper or foam.

Another plus of the wooden window block - high noise insulation, which allows you to reliably protect the home from extraneous noise. This is especially true if there is a constant source of noise in the place of residence (for example, a river, a road, a railway, etc.).

The first. The second and - obvious advantage of quality wooden windows is the natural warmth of the tree.

Wooden windows in wenge color in the Moscow high-rise building.

Only a window of wood is suitable for a country house.

The most important advantage that a wooden double-glazed unit has is the absence of condensation on them. This disadvantage is manifested in winter, at low temperatures, almost all plastic double-glazed windows. As a rule, condensate occurs in places where several temperatures (in a scientific way - a thermal bridge) of different temperatures occur. Such places are the seams, which are formed along the line of joining the frame and wall at the points where several dissimilar materials are connected.

To reduce the amount of condensate, the isotherms are usually counted and plotted. This is done in the production of windows, which allows you to install finished products without additional headaches for the owner of the premises. In this case, it is worth remembering that for poorly heated premises (for example, for a veranda) condensate is not terrible, since a small difference in temperatures inside and outside the premises does not contribute to its formation.

When installing a double-glazed window in a heated room, condensation often appears, because there is a big difference in temperatures (between street and home). In the case of strong frosts, condensation can become even frost or a thin ice crust, which contributes to uncomfortable location in the room. In this case, it is natural to form puddles that can damage machinery or carpets. It is also possible to damage the walls if condensate forms on them.

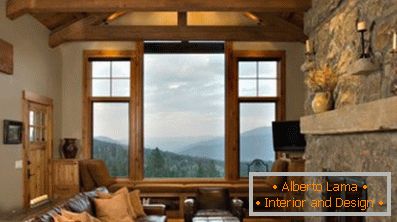

Spacious country style house (rustic) in the south of France.

Modern technologies in wood processing make it possible to produce windows that blend harmoniously with the architecture of the old building.

If the windows are wooden, the glass unit is installed correctly, then they are almost completely devoid of the above disadvantages, because the tree has a large number of micropores that allow the tree to "breathe". There is a natural heat exchange, the value of which for wooden double-glazed windows is in the range from 1 to 7 cubic meters of air per day. At the same time, the window (more precisely, the frame) "works", like a membrane that does not allow rain and cold to filter, filters the air that has passed into the room, but the temperature inside the room practically does not decrease.

The advantages of wooden double-glazed windows include the following:

- Execution of frames in any design for different needs (for example, for verandas or terraces country style will suit), including in the territory of one site for different buildings.

- Improved ergonomics in comparison with plastic and metal-plastic variants.

- The possibility of installing not only double-glazed windows, but also ordinary glasses (this will save money when glazing the verandas and other outbuildings).

- Stability of the material to temperature changes and to low temperatures.

- High maintainability.

However, wooden windows also have a number of shortcomings, which, first of all, are related to production technology. It is quite complex and can lead to errors, especially if the manufacturing enterprise increases the quantity of output produced at the expense of quality. Violation of technology and weak technological control - these two factors contribute to the appearance of defects, the most common of which is the deformation of the frame (when the tree "leads"). This is usually due to the fact that initially the wood was poorly dried.

Quality indicators of such products depend on drying, and on the wood itself (coniferous or deciduous). In order to reduce the likelihood of deformation when creating frames, multilayer beams are used (the timber is glued together from several layers of wood). It is worth noting that modern technology reduces the risk of deformation and other problems associated with poor-quality wood processing to low 7-10%.

Arched construction of a wooden window in a restored manor of the 19th century.

High wooden windows made of oak in the modern style living room.

Manufacturing of wooden windows

The technology of production of these products can be conditionally divided into several stages.

At the first stage, the material is dried. It is carried out for all types of wood in the production of windows, because the moisture molecules lead to a reduction in the strength and durability of the structure. For drying, the wood is first placed in a special drying storehouse, then into a drying chamber (dryer), after which the products are returned to the warehouse again. As a result, the moisture content of the material is 9-13%.

The next step is to make the cant. Recently, the most common technology has become a three-layer bar for windows. For its production, the wood is cut into small blocks, from the surface of which all defects are removed, creating an absolutely smooth surface. In this case, the bar is prepared in advance fasteners for joining with other bars in a single unit (eyes and a spike). After that, the docking surface is treated with adhesive materials, the bars are joined into a single bar. For a strong connection, the finished beam is placed under the press, where the glue hardens. The end of this stage is the grinding of the bar.

The next stage is the production of profiles for windows. The profile is made for frame, sash, window leaf, etc. Depending on what the bar goes on, the corresponding grooves are made in it. The process of production of blanks is fully automated, and all equipment automatically determines the dimensions of the workpiece according to the specified program, which makes it possible to produce windows of non-standard sizes.

Windows from the usual rectangular, to arched and round can be made by companies with modern technological equipment.

Wooden windows made of glued beams are not susceptible to deformation and are stronger than windows made from solid wood.

The following steps can be conditionally combined into one. They consist in processing the parts for the frame (or already assembled frame) and assembling the frame. A more acceptable option is the one in which the parts are treated with protective impregnations (from moisture, fire and priming) to assembly, but a number of manufactures do this already after assembly of the structure - this saves considerable material and finance, but often leads to a decrease in quality.

Next, proceed to control impregnation and painting the frame. The finished frame should be treated with impregnation again (double impregnation is recommended, but not all adhere to this technology), after which it is dyed or varnished. This provides protection from fungi, moisture, some resistance to mechanical damage, extends the life of the machine.

Installation of glass, gasket and accessories

The penultimate stage is the installation of glasses. It can be both multi-compartment units, and ordinary glass (usually used for glazing of verandas, terraces, etc.). In this case, the glasses can be anti-vandal, armored, fireproof, etc.

At the last stage, install seals, as well as accessories. Seals are usually made of modern polymer materials, and the accessories are selected by the customer, based on design and taste. The hardware usually includes locks (including the central), handles, various blockers, etc.

At the same time, quality control is carried out at all stages. All stages are controlled by electronics, and the last one examines the finished window, eliminates the identified shortcomings. After that, the product is packed (canned) and sent either to the customer or to the warehouse.

As can be seen from the description, the process is rather complicated and technologically advanced. At the same time, it is not possible to conduct a full-fledged quality control at all stages, and in some cases, there may be technology violations.

Wooden windows are harmoniously combined in the interior of the house with natural stone, plaster, brickwork and wooden flooring.

Creative design

Long gone are the times of standardization, when all living quarters (especially in apartment buildings) had almost identical windows.

Now everyone can pick up any design and any color of the frame.

You should start with the form. It can be not only rectangular, but also oval, round or have the appearance of any polygonal shape. The dimensions are not an obstacle. Now in fashion, 2 currents - minimalism (small windows) and maximalism (large). So, for a verandah large windows with a minimum of crosshairs are suitable, for corridors - small with different forms of crosshairs, etc.

You should pay attention to the processing of wood - the ability to make carved patterns, texture, etc. Another advantage is the opportunity to select thematic stained glass windows that will complement the design of the house.

All this allows you to choose windows for every taste and for any landscape design.

Modern wooden windows and their features. Video

Advantages of modern wooden windows

37