To determine the quality of wooden furniture does not necessarily have to be an expert. All you need to do before buying new furniture from wood is to look at its material, design, finish and take your time. Our article will acquaint you with the main points concerning the choice of reliable wooden furniture.

Materials

Today, furniture is made from a variety of wood, which can be hard, soft or engineering. Which type of tree was used is one of the main factors determining how long your furniture will serve you, and how its species will change with age.

The most high-quality furniture for today is produced from solid wood Hardwood trees such as oak, maple, teak, walnut, cherry, birch, ash and poplar. Such materials are characterized by high strength and stability. In this case, the wood can be dried in air, and then - in an oven, which removes all moisture from it and makes the tree resistant to deformation, splitting and cracking.

Teak Furniture

Coniferous trees, such as pine, spruce and cedar, are used to obtain the so-called "Soft" wood. You can find good quality furniture and of such materials, but still they are more prone to scratches and dents on their surface, and therefore require more care.

Furniture from a tree of a pine

It is worth noting that furniture from solid wood all the more noticeably fades into the background. You can still easily find it in stores, but most often there are products that were made from plywood or chipboard material, also called fiberboard or MDF.If the material consists of pieces of wood - this is plywood. It can have from 3 to 5 thin layers of wood, glued together under high pressure.

Veneer sheets

When small particles or shavings (fibers) left after the wood is chopped into sawn timber, are joined, glued and pressed together - this is called particleboard or fiberboard. If the density of fibers is not lower than average, this material provides good strength of wooden furniture, and also helps to prevent splitting or deformation, and therefore it is quite worthy of consideration.

Sheets of chipboard

By the way, to ensure greater impact strength, MDF or MDF is often laminated - the surface is covered with a layer of plastic, foil or paper, on which a wood pattern is printed.

Sheets of laminated chipboard

Design

The way wooden parts are connected to each other in the process of making furniture, largely contributes to its beauty, functionality and, what is more important, longevity. Joinery and bond strength can tell you a lot about the quality of the product you are going to buy.

"Paz-spike" and "swallow-tail" are the two oldest ways to combine wooden parts, as well as the most durable and most beautiful compounds. A good grip also gives dowels or screws, but in no case a stapler. In addition, in quality furniture, the use of glue should not be noticeable.

Furniture from a tree - connection "groove-thorn"

Furniture made of wood - dovetail

When buying wooden furniture, you should pay attention to the presence of corner blocks, which give it stability. They are not visible from the outside, but are bolted on both sides of the inner corners.

Furniture from a tree - fastening of corners

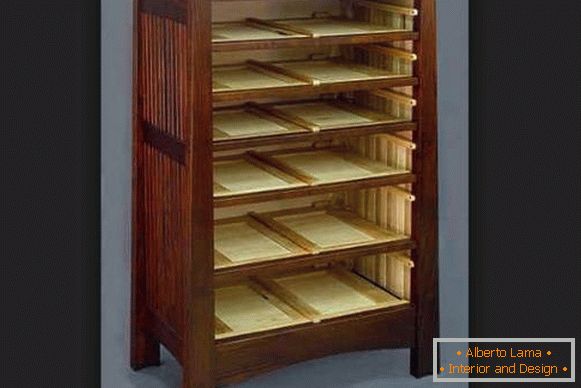

A table or chest of good quality should have special panels or thin sheets of wood between the boxes. This not only strengthens their structure, but also prevents particles of dust from getting into clothes or documents.

Anti-dust panels between chest drawers

Do not forget to check whether the boxes fit well and slide, and whether they have special stops that do not allow the drawer to fully extend and drop the box to the floor.Back furniture panels that face the wall are usually fastened with screws to ensure lateral stability. Backs and hidden parts should be smoothly ground and well adapted - this is an important feature for such furniture.

The doors must be closed neatly, without a sharp knock and remain level with the body when they are opened. Look closely at the hardware (latches, handles, drawer guides, hinges

В завершение осмотра протестируйте изделие, попытавшись раскачать или толкнуть его. Design не должна скрипеть и накреняться.

Finish

High-quality furniture made of wood must have a good finish. Grinding, painting and applying a protective coating are the main components of this process, and lack of care at any stage can affect the overall quality of the product.

Sanding is the first step in the process of finishing wooden furniture. The surface of the product should be smooth when you hold it over your hand, without any rough areas that slow down the movement. Sanding across a wood texture often leads to such an unattractive result as dark lines or scratches on the entire surface. In addition, the wrongly ground wood can not be uniformly colored. Examine the finish from different points of view to check for the presence of stains and scratches.

Poor-quality finish of wooden furniture

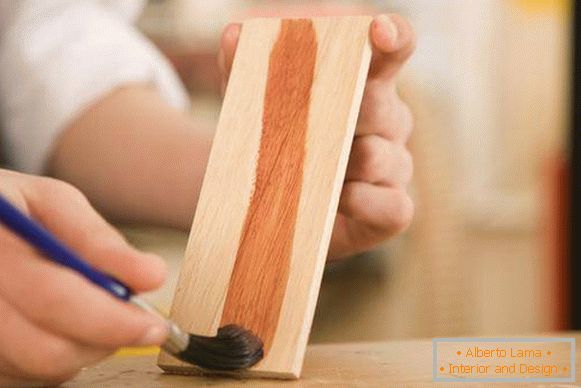

A good paint emphasizes the natural beauty of the tree, adds color and character to it. It also allows one kind of tree to look like the other, or makes different timber look the same. Coloring of high quality should not have any dark spots. All sides and angles should be the same tone.

Painting of wooden furniture

Painting of wooden furniture

Wood can also have a variety of coatings - from glossy to matte. A truly high-quality coating is satin-smooth, without any roughness, grains or bubbles. The most luxurious finish has several thin layers of coating, each of which has been neatly ground. The best furniture made of wood has a coating not only on the front surfaces, but also on the back and bottom, which reduces its chances of swelling, shrinking and cracking.Proceeding from all of the above, we will outline the main features of a poorly finished tree:

- surface roughness;

- too shiny or opaque coating that hides the texture of the tree;

- split edges;

- scratches, dents or grains;

- dim spots that indicate missed areas and careless handling of the coating;

- frozen "tears" on the edges and on the vertical surfaces of furniture.

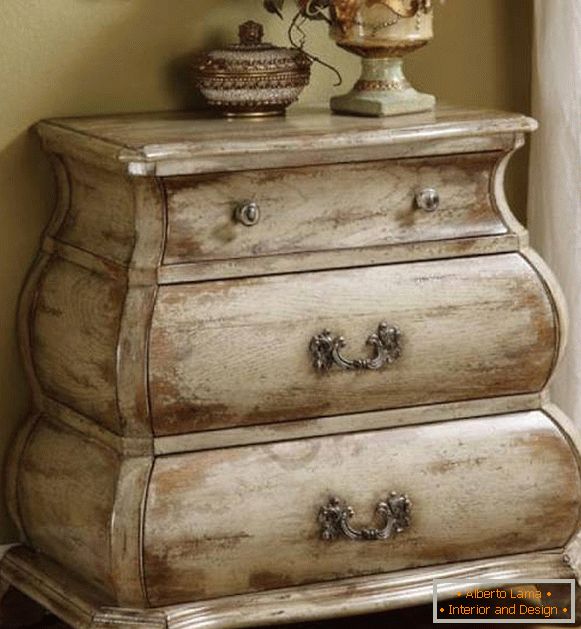

An exception in this case can be considered artificially aged furniture made of wood. Many designers today use similar effects to give the furniture a rustic "country" style. Wood is specially beaten, cut and scraped, after which a protective coating is applied, which does not allow the paint to split, to appear splinter

Artificially aged furniture made of wood

Artificially aged furniture made of wood