Most modern residential and commercial wallpaper is produced using surface, flexographic, stencil and gravure printing. But it is quite natural that many manufacturers, striving to surprise their customers, often produce even more unusual wallpaper models, experimenting with old or, on the contrary, innovative methods of drawing a picture. In this article, you will learn about all the ways in which in the modern world beautiful patterned wall coverings are created.

Surface printing

This is the oldest automated printing method, which is often used in the production of wallpaper, given that today no one is releasing a machine for this. All the devices that are used for surface printing these days, were made no later than 1948, so they are very carefully guarded.

An image of an early surface printing machine

On the surface of the wallpaper is abundantly applied ink, which slightly spread on the paper, because of what the finished image is not as clear as when using other methods. In addition, in machines for surface printing, there are no "dryers" between different color stations, so that ink of different colors can be mixed slightly with each other. For these reasons, the wallpaper pattern turns out to be quite a specific kind - its unique texture and unpredictable paint play are very reminiscent of hand painting.

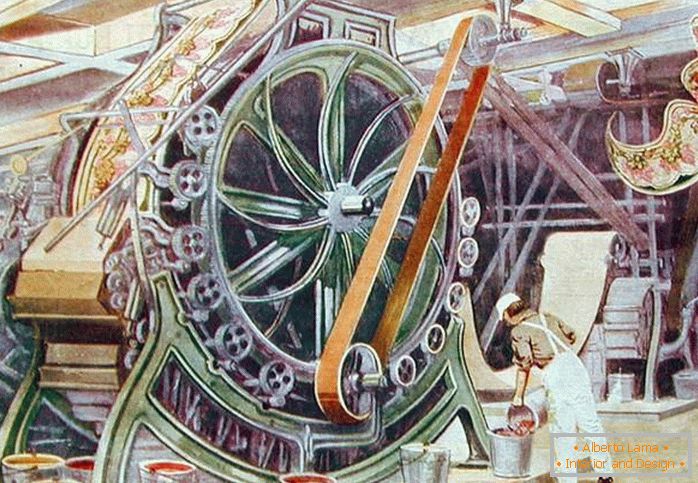

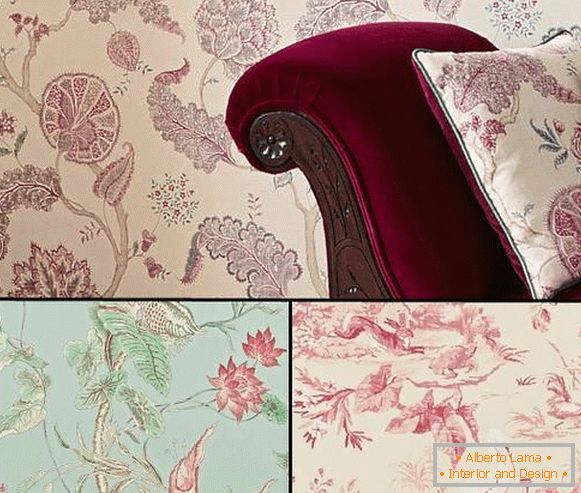

Wallpaper with a surface print pattern. Manufacture Sanderson

Particularly well, this method of printing is suitable for creating picturesque floral patterns and wallpaper of classical design. The ability to use multiple shades simultaneously is limited to 12 colors.Флексографическая печать

The name of the updated version of the surface print comes from the Latin "flexibilis", which means "flexible". Flexography, first applied in England around 1900, is carried out using flexible rubber cylinders or rollers.

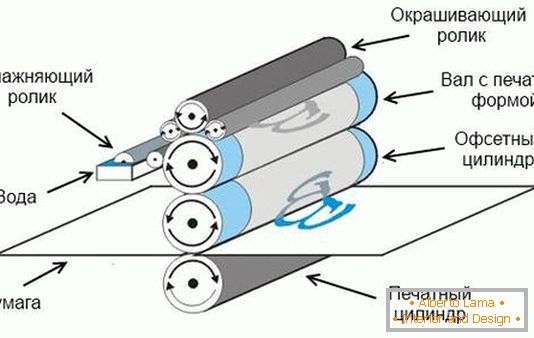

Scheme of flexographic printing process

Inks are transferred to paper from a special shaft on which a relief pattern was engraved. With traditional surface printing, this shaft is made of very hard material, but flexo rubber allows the use of less ink and provides higher image accuracy.

Wallpapers from Designers Guild, produced using flexography

Unlike all other printing methods, flexography can transmit an approximate view of drawings made with surface, deep or screen printing. Typically, flexo printing machines use 7 or 8 colors, but some of them allow the application of up to 12 shades.Screen printing

A century and a half ago, drawing a picture on a wallpaper through a stencil could only be done manually, but today it uses a fully automated process, which is the most expensive of modern printing methods.

When using this method, the ink is applied to the wallpaper through holes in hollow cylindrical screens (stencils) arranged one after another in a certain order. Usually for wallpapers it is enough to use 7-8 different colors (one color is supplied to each cylinder). If you need to get more shades, then the wallpaper passes through the machine twice (or even more, depending on the need) - each time with a new set of ink, which significantly increases the cost of wall covering.

Screen Printing Machine

A distinctive feature of screen printing is the possibility of obtaining bright opaque shades and clearly delineated shapes. In addition, after each application of one specific color, the wallpaper is quickly dried, so that the colors applied on each other do not mix.

Wallpaper with screen printing. Production of Borastapeter

Deep (gravure) printing

To transfer images to paper, gravure printing uses a hard engraved cylinder, but unlike rollers used for surface and flexographic printing, the image on it is not convex, but drowned.

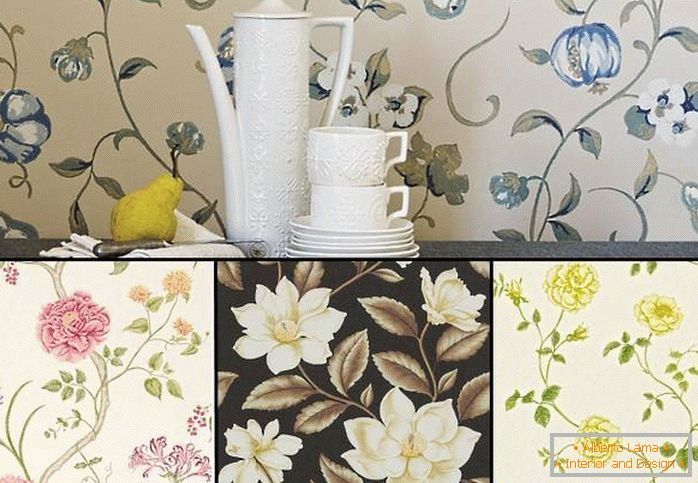

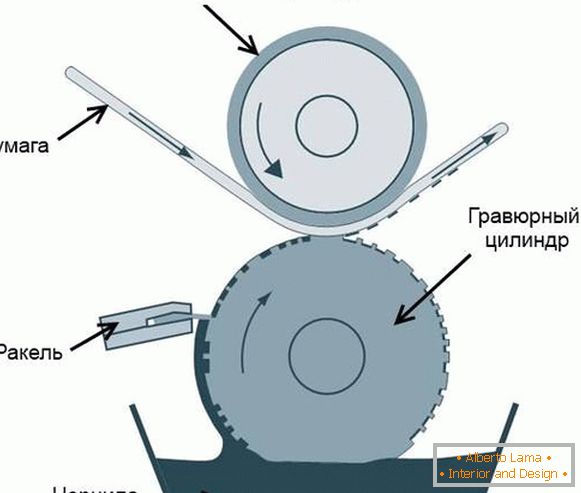

Scheme of the process of gravure printing

The ink is collected in the recesses of the cylinder and absorbed by the paper as it passes through it. The more intense the shade of these or those elements of the pattern should turn out, the deeper there must be certain depressions, and the more ink it will take for them.

The number of shades can be essentially unlimited, but as a rule, for most wallpapers it's enough to use 6-8 different colors, including the background color.

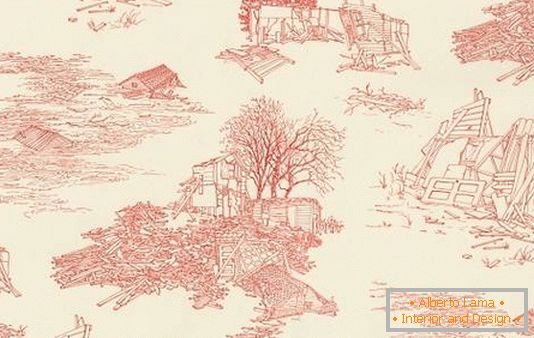

The method of intaglio printing involves drawing the majority of wallpaper and wallpaper borders, which duplicate the appearance of photographs and realistic art.

Sanderson wallpaper, made by gravure

Lithography (offset printing)

Unlike all other printing methods, this method is performed using an absolutely flat shape, the drawing of which is transferred to paper under pressure.

Scheme of the process of offset (lithographic) printing

At the heart of modern lithography is one of the earliest methods of drawing a wallpaper pattern. Initially, the image was painted in bold ink or crayons on specially prepared limestone. After the image was washed off with water, which moistened the stone only in places where before this figure was not. On this moistened stone roller was applied to printing ink, which, on the contrary, was repelled by water and pestered only to places corresponding to the pattern. Then, on a special machine, the paper was pressed against the stone and thus a pattern appeared on it. In modern lithographic printing methods, aluminum cylinders are used as a print medium.

Wallpaper made with lithography

Shelkography

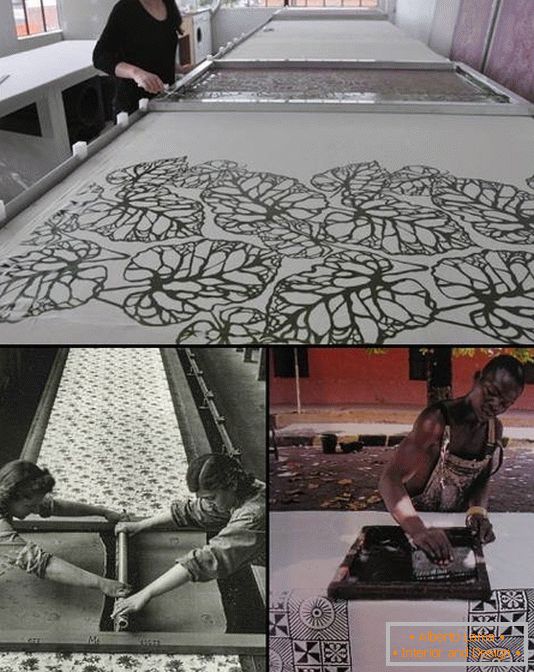

Shelkography является ручным способом нанесения узора на обои, который осуществляется с использованием специальных рамок и трафаретов.

The paint is applied to a frame covered with silk, polyester or nylon, and penetrates into areas that are not covered by a stencil pattern. Using several such frames, you can add any number of shades to the wallpaper, successively applying the necessary layers of paint. The seal itself is directly carried out by a special squeegee, which is carried on the stencil from above.

Different ways of silkscreening

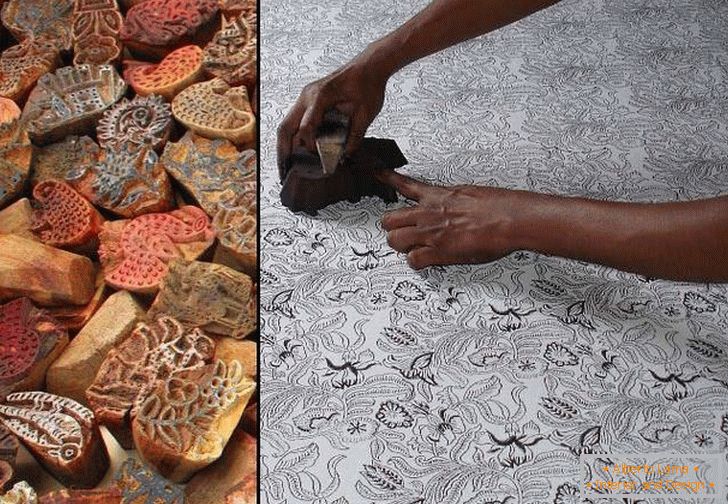

Block Printing

This manual printing method is the forerunner of the surface patterning technology and in general the very first printing method in the world.

Block Printing осуществляется при помощи резных деревянных блоков (как правило, используется по одному такому блоку для каждого цвета), которыми мастер выдавливает узор на бумажном полотне. После нанесения самых крупных элементов наступает черед наносить узоры помельче, что требует от мастера еще большей аккуратности и терпения.

Wooden forms for block printing of a pattern

Printing this way takes a lot of time and is a very laborious process, so the wall coverings, painted in this way, today are among the most expensive. But everyone has a sure way to get to know them - go to the museum.

Wallpaper, painted with blocks. William Morris, 19th Century

The methods of printing and the corresponding types of wallpaper for the walls listed above can boast a rather long history of their development, since they were invented at least two centuries ago. So, for example, in China samples of block printing that were made in the III century were found!But none of these methods of printing wallpapers can provide such high image quality and print speed, which became available with the advent of modern digital equipment.

Digital printing of wallpaper

Digital printing of wallpaper обеспечивает как скорость, так и высокое качество печати. Этот метод подготовки обоев не имеет такой долгой истории, как другие виды обоев для стен, о которых шла речь в этой статье. Но уже сейчас цифровая печать обоев уже имеет множество собственных разновидностей, которым и посвящена следующая статья.